High Volume PCB Assembly: Efficiency, Precision, and Scalable Production for Modern Electronics

As electronic products scale and global demand grows, high volume PCB assembly has become one of the most crucial manufacturing capabilities for brands that need consistent quality at industrial production levels. Whether for consumer electronics, automotive systems, medical devices, telecommunications equipment, or industrial automation, high volume PCB assembly ensures that thousands—or even millions—of units are produced with identical performance, reliability, and compliance. This manufacturing category requires advanced automation, stringent quality control, and optimized production flow to deliver rapid output without compromising accuracy.

Understanding High Volume PCB Assembly

What High Volume PCB Assembly Means

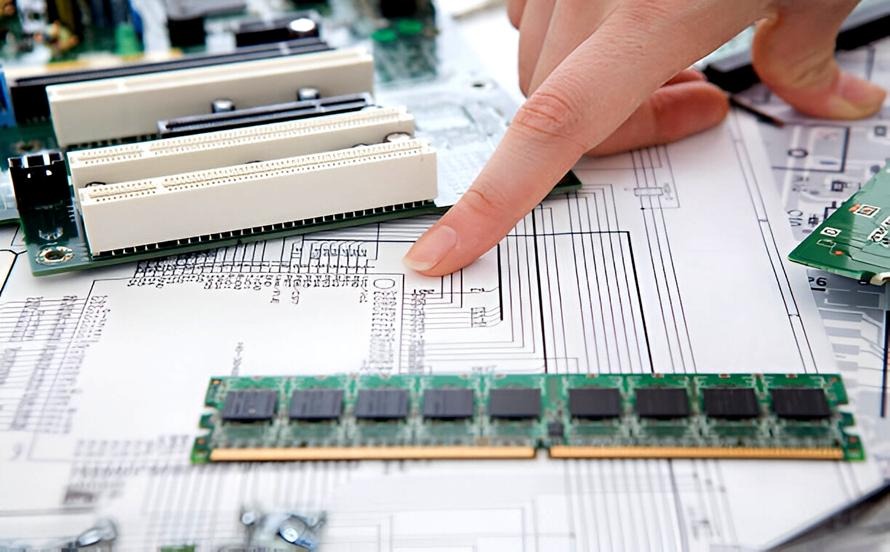

High volume PCB assembly refers to the mass production of printed circuit boards on fully automated lines capable of handling large quantities with minimal manual intervention. While prototype and low-volume production focus on flexibility, high-volume assembly focuses on repeatability, speed, and process stability. Every board in the batch must meet the same specifications, tolerances, and functional requirements.

This type of assembly relies heavily on high-speed pick-and-place machines, automated stencil printing, inline inspection systems, and reflow ovens designed to handle dense boards at scale. The primary goal is to streamline production while achieving optimal yield and consistent output.

Why High Volume Production Matters

As product lifecycles become shorter and consumer demand becomes more dynamic, manufacturers need reliable high-volume production to keep up. High volume PCB assembly allows businesses to introduce products faster, reduce unit cost, and maintain uninterrupted supply. Companies in competitive markets benefit significantly from mass manufacturing because it ensures they can scale without delays or bottlenecks.

Key Stages of High Volume PCB Assembly

Solder Paste Printing and Automated Placement

The process begins with precise solder paste deposition using automated stencil printers. For high volume PCB assembly, consistency in solder application is essential because any deviation affects every board downstream. High-speed pick-and-place systems then position components with exceptional accuracy, often handling tens of thousands of placements per hour. This ensures that even complex boards featuring tiny components like 01005 packages or fine-pitch ICs are assembled reliably.

Reflow Soldering and Thermal Profiling

After placement, the boards move through reflow ovens where controlled heating zones melt and solidify the solder to secure all components. For large batches, the thermal profile must be optimized to ensure every board receives uniform heat exposure. This is especially important for mixed-technology assemblies that include BGAs, QFNs, power components, and sensitive ICs.

Wave Soldering or Selective Soldering for Through-Hole Parts

In cases where through-hole components are involved, wave soldering or selective soldering is integrated into the production line. High volume PCB assembly prioritizes efficiency, so automated soldering is essential for maintaining uniformity and preventing defects like bridges or insufficient joints.

Inspection and Quality Control

Inline AOI (Automated Optical Inspection) systems examine every board for placement issues, solder defects, polarity errors, and alignment problems. For high volume manufacturing, AOI is non-negotiable, as manual inspection is too slow and prone to error. X-ray inspection is used for hidden-joint components such as BGAs, ensuring complete visibility into solder ball integrity.

Functional Testing and Packaging

Before shipment, assembled boards undergo various electrical and functional tests to verify performance. Flying probe, ICT (In-Circuit Testing), and custom test fixtures ensure batch-level consistency. Once approved, the boards are packaged using ESD-safe materials and prepared for logistics.

Industries That Rely on High Volume PCB Assembly

Consumer Electronics and Smart Devices

From smartphones and tablets to wearables and household electronics, large-scale production is essential for meeting global demand. High volume PCB assembly ensures that every device performs identically and meets strict reliability expectations.

Automotive and EV Manufacturing

Modern vehicles rely on multiple PCBs for engine control, safety features, infotainment, battery management, and ADAS systems. These applications require high-volume output backed by automotive-grade quality and compliance with standards like IATF 16949.

Telecommunications and Networking Hardware

Routers, switches, antennas, fiber optics equipment, and telecom infrastructure hardware all require high-volume production to support large-scale deployments.

Medical and Industrial Applications

High volume PCB assembly helps produce medical monitors, diagnostic devices, sensors, industrial control systems, and robotics that must function flawlessly and consistently.

Why High Volume PCB Assembly Delivers Efficiency and Cost Advantages

High volume production reduces per-unit manufacturing costs due to economies of scale. Automated equipment minimizes human error and speeds up production cycles. Component sourcing is also more efficient because manufacturers purchase materials in bulk, ensuring both availability and competitive pricing. This level of efficiency makes high volume PCB assembly the ideal solution for businesses planning large market releases.

Conclusion: Scale Your Product Seamlessly with a Trusted Partner

Choosing the right partner for high volume PCB assembly ensures that your electronic products are manufactured with the precision, speed, and consistency needed for large-scale success. From automated production lines to rigorous quality testing, an experienced manufacturer delivers dependable output at competitive costs. If you are ready to scale your next project, working with a reliable provider of PCB assembly services will help you achieve fast turnaround, exceptional build quality, and seamless mass production for any electronic design.