Electronic Manufacturing Process: A Complete Guide to How Modern Electronics Are Built

The Electronic Manufacturing Process is the foundation of every device we use today—smartphones, medical instruments, automotive control units, industrial machines, aerospace systems, and consumer gadgets. Behind every functional electronic product lies a carefully optimized series of steps that ensure performance, reliability, and safety. As electronic devices become smaller, faster, and more complex, understanding the Electronic Manufacturing Process is more important than ever for designers, startups, OEMs, and companies bringing new technology to market.

The process spans everything from initial circuit design to the final packaged product. Each stage requires high precision, advanced machinery, strict quality standards, and experienced engineering support. Below is a complete breakdown of how the Electronic Manufacturing Process works and why it remains a critical part of modern technology development.

What Is the Electronic Manufacturing Process?

The Electronic Manufacturing Process refers to the complete lifecycle of building an electronic product. It includes design, PCB fabrication, component sourcing, assembly, inspection, testing, and final product integration. Every phase is interconnected—meaning that quality errors in one step can cause failures or low performance later in the product’s life.

Modern electronics manufacturing relies heavily on automation, advanced surface-mount technology (SMT), AI-driven inspection systems, and strict cleanliness standards. With industries demanding high-density PCBs, miniaturized components, and zero-defect production, the Electronic Manufacturing Process has evolved into a precise and highly controlled system.

1. Design Engineering and Prototyping

The Electronic Manufacturing Process begins with the design phase. Engineers create electrical schematics, choose suitable components, and simulate the circuit’s performance under different conditions. After this, PCB layout engineers convert the schematic into a practical board design, ensuring correct trace widths, impedance control, heat distribution, and signal stability.

Prototyping is then performed to test the initial design. This step verifies component placement, functional performance, and manufacturability. Early prototyping helps identify issues before mass production begins, saving time and cost.

2. PCB Fabrication

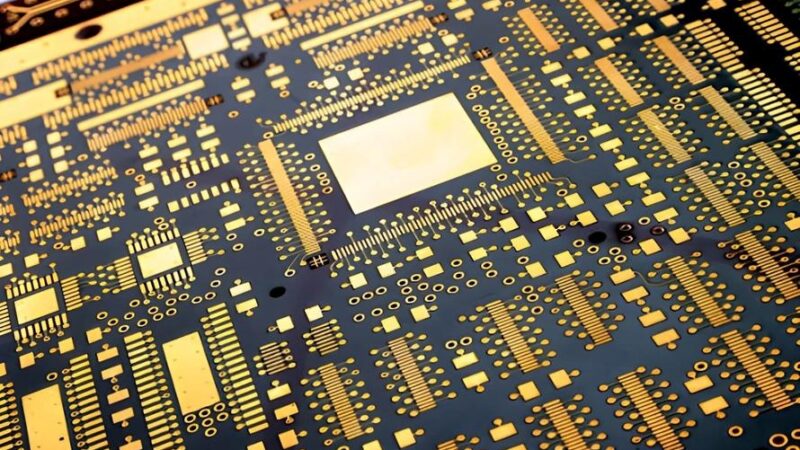

Once the prototype is approved, manufacturers begin PCB fabrication. This is one of the most important parts of the Electronic Manufacturing Process, as the quality of the PCB affects the device’s lifespan and performance.

The PCB fabrication process includes:

- Layer stack-up planning

- Photo-imaging

- Chemical etching

- Drilling and via formation

- Copper plating

- Lamination

- Solder mask application

- Silk-screen printing

- Surface finishing (ENIG, HASL, OSP, immersion silver, etc.)

Modern boards may include microvias, buried vias, blind vias, controlled impedance, heavy copper, or high-frequency materials depending on the application.

3. Component Sourcing and BOM Management

Every electronic product requires reliable components—from resistors and capacitors to semiconductors, connectors, and sensors. The sourcing stage focuses on purchasing high-quality parts from trusted distributors while avoiding counterfeit components.

Manufacturers must monitor:

- Part availability

- Lead times

- Cost efficiency

- Component lifecycle status

- Authenticity and certificates

- Alternatives for at-risk components

Clear and accurate BOM (Bill of Materials) management is critical to preventing delays or production failures.

4. SMT Assembly (Surface-Mount Technology)

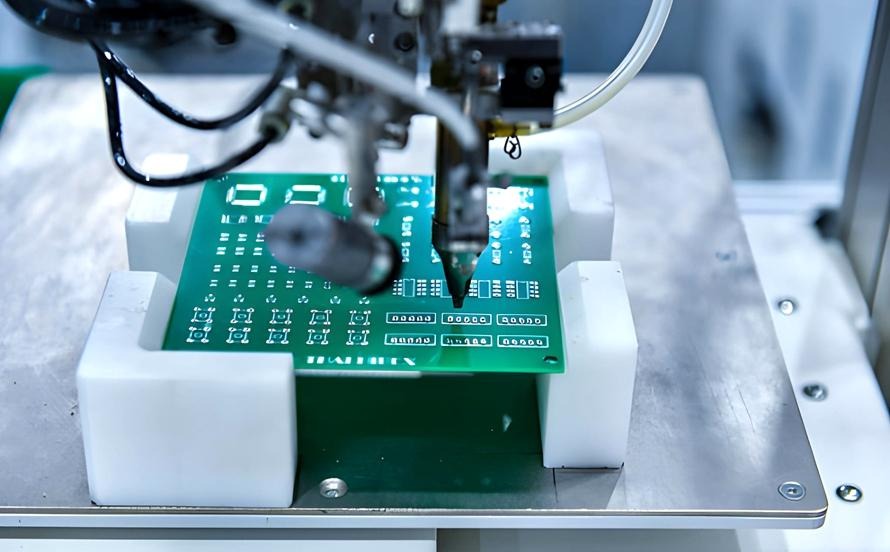

The heart of the Electronic Manufacturing Process is the SMT assembly line. Most modern electronics use surface-mount components due to their smaller size and higher performance.

SMT assembly involves:

- Solder paste printing on PCB pads

- Pick-and-place machines positioning components

- Reflow soldering to permanently bond components

- AOI (Automated Optical Inspection) after reflow

High-speed SMT lines can place thousands of components per minute with exceptional accuracy. For advanced packages like BGA, QFN, or micro-BGAs, X-ray inspection is used to detect hidden solder defects.

5. Through-Hole Assembly

Although SMT dominates the modern Electronic Manufacturing Process, some components still require through-hole technology (THT). These include mechanical connectors, transformers, relays, and large capacitors.

Through-hole assembly can be:

- Manual soldering

- Automated insertion

- Wave soldering

- Selective soldering

THT components provide high mechanical strength, making them essential for industrial and automotive electronics.

6. Inspection and Quality Control

No Electronic Manufacturing Process is complete without strict inspection and testing. Each board goes through industry-standard verification stages:

- SPI (Solder Paste Inspection)

- AOI (Automated Optical Inspection)

- X-ray inspection for hidden joints

- ICT (In-Circuit Testing)

- Functional testing

- Burn-in and stress tests

Following IPC-A-610, ISO, and customer-specific standards ensures every product meets reliability and safety requirements.

7. Final Assembly, Packaging, and Delivery

After PCB assembly passes all inspections, the electronics move to final assembly. Here, PCBs are integrated into their housings with wiring, connectors, displays, batteries, sensors, and mechanical parts. Final testing is performed to simulate real-world usage.

Once complete, products are cleaned, labeled, packaged, and prepared for shipping.

Why the Electronic Manufacturing Process Matters

A smooth Electronic Manufacturing Process ensures:

- Reliable, long-lasting electronics

- Reduced production costs

- Faster time-to-market

- Stronger product performance

- Compliance with global standards

- Minimal defects and failures

Companies that understand this process can develop more competitive and advanced products.

Conclusion: Choose the Right Partner for Your Electronic Manufacturing Process

To succeed in today’s competitive electronics industry, partnering with an experienced and reliable manufacturing provider is essential. A company like Viasion Technology can streamline your entire Electronic Manufacturing Process—from prototype to mass production—ensuring high quality, competitive pricing, and on-time delivery. Whether you’re launching a new product or scaling an existing design, choosing the right manufacturing partner will determine your success in the global electronics market.